Vancouver, Canada -- Mawson Resources Limited ("Mawson") or (the "Company") (TSX:MAW) (Frankfurt:MXR) (PINKSHEETS: MWSNF) announces results from preliminary metallurgical testing on drill core from the Palokas prospect at the Rompas-Rajapalot gold project in Arctic Finland by SGS Mineral Services UK in Cornwall.

Key Points:

|

Mr Hudson, the Company's President & CEO, states, "This is a significant outcome. Although we have seen visible gold in hand specimens and thin sections, it is encouraging to see that these results demonstrate gold extraction at Palokas is amenable to a conventional flowsheet with up to 99% recoveries. Drilling with the low impact core sampler continues up to 1 kilometre south of Palokas."

Four composite samples from drill holes PRAJ0003 (2.0 g/t gold), PRAJ0006 (12.4 g/t gold), PRAJ0009 (1.8 g/t gold ) and PRAJ0026 (0.7 g/t gold) were provided from half or quarter EW (25mm diameter) drill core to SGS Mineral Services UK in Cornwall (Table 1 and Mawson Press Releases October 03, 2013, October 16, 2013 and January 20, 2014). Metallurgical response of these composites to gravity separation and cyanide leach were determined as shown in Table 2 and below.

| Drill Hole Composite |

SGS Head Grade (gold g/t) |

Total Gravity Extraction |

Total Leach Extraction |

Overall Extraction |

|---|---|---|---|---|

| PRAJ0003 | 2.4 | 35 % | 63 % | 98 % |

| PRAJ0006 | 20.7 | 48 % | 51 % | 99 % |

| PRAJ0009 | 1.1 | 42 % | 53 % | 95 % |

| PRAJ0026 | 0.8 | 26 % | 71 % | 97 % |

Sequential leach tests on the four samples indicate no gold is locked within the sulphide minerals although there is an association between gold and sulphides, which suggest flotation may be a viable process for further study. Internal consistency of recoveries across the four samples and back calculating of grades gives a high level of confidence in these results and in assays reported to date by Mawson (Table 3). The next phase of test work will review mineralogical gold deportment, whole ore cyanidation, complete gravity recoverable gold tests, comminution and grinding studies, kinetic studies of gold leaching and cyanide consumption, flocculent selection, thickening and filtration and environmental testing of tailings.

In other news, as previously reported, Mawson has been dealing with certain Finnish environmental authorities in regards to work completed during the 2010 and 2011 field programs. The issue involves allegations that the Company's hand digging from these programs affected the nature values of the area where the work was undertaken. The pre-hearing and field visit for the case occurred on October 14 and 15, 2014. The full hearing is scheduled for November 3, 4, 6 and 7, 2014 in the Kemi-Tornio District Court. Mawson is pleased the case has advanced after 4 years through formal legal processes. Mawson believes the claims made are without merit and will vigorously defend itself and its employees. Mawson has always maintained that hand digging had no material impact on the nature values of the area in question. Mawson believes it conducted its operations within the intent and law of the Mining and Nature Conservation Acts.

About Mawson Resources Limited (TSX:MAW, FRANKFURT:MXR, PINKSHEETS:MWSNF)

Mawson Resources Limited is an exploration and development company. Mawson has distinguished itself as a leading Nordic Arctic exploration company with a focus on the flagship Rompas and Rajapalot gold projects in Finland.

Technical Background

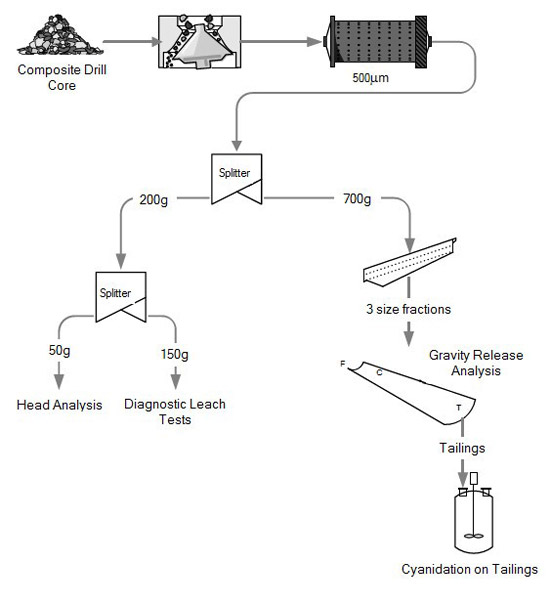

Samples were shipped by air to SGS Mineral Services UK in Truro, Cornwall where they were weighed (dry) and sieved with a square aperture 500 micron sieve and the remaining sample was progressively crushed in a cone crusher and a TEMA ring and puck mill until all sample passed through the sieve. A split of 200 g of the minus 500 micron material was pulverized and a further split of 50g was separated for head grade analysis with the remaining 150 g used for the diagnostic leach tests. The remaining 700g of - 500µm crushed sample was retained for gravity release and cyanidation tests. Figure 1 presents the diagrammatic flowsheet of the process.

The gravity release analysis comprised of three screened size fractions, -500µm to +212 µm, -212µm to +75µm and -75µm to + 10µm. The -10µm (fines) fraction was removed using a Warman cyclosizer and analysed for gold. Each size fraction was concentrated using a Mozley Laboratory Mineral Separator. The tailings from the different size fractions of Gravity Release Analysis for each sample was pulverised in a TEMA ring and puck mill, blended and tested for gold recovery using cyanide as the leaching agent. A subsample of the blended feed material was sent for gold analysis. The blended charge was placed in a bottle and pulped to 33% solids using DI water. The pH was then adjusted using lime (CaO) to between 10.5 and 11 and allowed to stabilize. Cyanide was then added to bring the solution concentration to 0.5 g/l CN. The bottle was placed on a roller deck where it was continuously rotating for a 48-hour leach period. Periodic titrations of the leach solution were made to monitor and facilitate adjustment of the cyanide concentration to maintain the starting test conditions. Periodic checks were also made on the pH of the solution and adjusted where required. All measurements and reagent additions were recorded to facilitate calculation of reagent consumption for each of the tests. At the end of the 48-hour leach period, a final solution titration and pH record were taken. A final solution sample and a washed solid residue sample were submitted for gold analysis to allow metallurgical balancing of the test results to be completed.

The diagnostic cyanide leach test was conducted on a representative 150g sample of the pulverised ore. The rationale of the diagnostic leach test is that the least stable mineral present in the matrix of the sample is first eliminated in aqueous media using a selective oxidative leach and then cyanidation is used to extract the gold liberated by the destruction of this mineral. The gold extracted is then measured in solution to give a reasonably accurate record of the amount of gold associated with that mineral. The residue from this first stage is subjected to a more oxidative acid leach and the process repeated.

The qualified person for Mawson's Finnish projects, Mr Michael Hudson, President & CEO for Mawson and Fellow of the Australasian Institute of Mining Metallurgy has reviewed and verified the contents of this release.

|

On behalf of the Board, "Michael Hudson" |

Investor Information |

Forward Looking Statement

This news release contains forward-looking statements or forward-looking information within the meaning of applicable securities laws (collectively, "forward-looking statements"). All statements herein, other than statements of historical fact, including statements regarding anticipated exploration activities and the intended financing are forward-looking statements. Although Mawson believes that such statements are reasonable, it can give no assurance that such expectations will prove to be correct. Forward-looking statements are typically identified by words such as: believe, expect, anticipate, intend, estimate, postulate and similar expressions, or are those, which, by their nature, refer to future events. Mawson cautions investors that any forward-looking statements are not guarantees of future results or performance, and that actual results may differ materially from those in forward looking statements as a result of various factors, including, but not limited to, capital and other costs varying significantly from estimates, equipment failure, unexpected geological conditions, permitting, operational delays, environmental and safety risks, and other risks and uncertainties disclosed under the heading "Risk Factors" in Mawson's most recent Annual Information Form filed on www.sedar.com. Any forward-looking statement speaks only as of the date on which it is made and, except as may be required by applicable securities laws, Mawson disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise.

Table 1: Continuous Composite Samples Provided to SGS Mineral Services UK

| HoleID | Easting | Northing | From (m) | To (m) | Interval (m) | Au (g/t) |

|---|---|---|---|---|---|---|

| PRAJ0003 | 3408688 | 7373822 | 5.0 | 9.0 | 4.0 | 2.00 |

| PRAJ0006 | 3408686 | 7373839 | 10.3 | 15.3 | 5.0 | 12.42 |

| PRAJ0009 | 3408711 | 7373854 | 22.7 | 27.4 | 4.7 | 1.81 |

| PRAJ0026 | 3408693 | 7373856 | 20.0 | 24.9 | 4.9 | 0.73 |

Table 2: Gold Extraction Results

| HoleID | SGS Head Grade (gold g/t) |

Gravity Extraction -500µm+212 µm |

Gravity Extraction -212µm+75 µm |

Gravity Extraction -75µm+10 µm |

Total Gravity Extraction |

Total Leach Extraction |

Overall Extraction |

|---|---|---|---|---|---|---|---|

| PRAJ0003 | 2.4 | 6% | 12% | 17% | 35 % | 63 % | 98 % |

| PRAJ0006 | 20.7 | 7% | 15% | 25% | 48 % | 51 % | 99 % |

| PRAJ0009 | 1.1 | 3% | 12% | 26% | 42 % | 53 % | 95 % |

| PRAJ0026 | 0.8 | 2% | 11% | 14% | 26 % | 71 % | 97 % |

Rounding errors lead to arithmetic summing differences

Table 3: Comparison of assayed and calculated gold grades

| HoleID | SGS Head Grade (gold g/t) |

SGS Back Calculated Gravity (gold g/t) |

SGS Back Calculated Diagnostic Leach (gold g/t) |

Mawson geochemical assay (gold g/t) |

|---|---|---|---|---|

| PRAJ0003 | 2.4 | 1.8 | 1.77 | 2.00 |

| PRAJ0006 | 20.7 | 15.7 | 13.45 | 12.42 |

| PRAJ0009 | 1.1 | 1.9 | 1.86 | 1.81 |

| PRAJ0026 | 0.8 | 0.9 | 0.95 | 0.73 |

The direct head analysis of the samples gave gold grades were slightly deviant from the back calculated assays, but, there is a good correlation between the back calculated grades from the gravity analysis and the diagnostic leach tests. The most variance in the grade was seen for PRAJ0006 which was the highest grade sample of the four. This is due to the presence of coarse nuggets which results in an inherent error due to sampling at a coarse size. The least variance was seen for PRAJ0026 which is the lowest grade sample and which contained the least amount of free and liberated coarse gold.

Figure 1. Flow diagram of the testwork program (Courtesy SGS Mineral Services UK)